Come and take a look behind the scenes at Derriere Equestrian Production

Underwear comes in every shape and size, with a plethora of choice when it comes to style. The meticulous underwear design technology applied at Derriere Equestrian is radically different from the undergarment industry status quo. Team Derriere Equestrian take you behind the scenes at our manufacturing facilities in Italy and Tunisia.

Underwear comes in every shape and size, with a plethora of choice when it comes to style. The meticulous underwear design technology applied at Derriere Equestrian is radically different from the undergarment industry status quo. Team Derriere Equestrian take you behind the scenes at our manufacturing facilities in Italy and Tunisia.

From the clothing we wear, to the technology at our fingertips, to the food we eat, we have an insatiable curiosity about how things work and are made.

Our factories in Tunisia lead the world in designer lingerie manufacturing courtesy of their dedicated, highly skilled work force coupled with the very best equipment. Our production team, headed-up by Claire Galer, have an incredible eye for detail and quality so that every one of our designs stands up to the closest scrutiny. Make no mistake, this is a very competitive business and so efficiency, productivity and quality control are the vital ingredients to making a garment that will be successful in the marketplace.

Derriere Equestrian is all about quality and this is why we source the very best luxury, high performing sporting fabrics from Italy; this is the key to our underwear feeling so comfortable and conforming.

All our designs are rigorously performance tested and tweaked, if necessary, until we are 100% confident that they will surpass expectations. The latest, and most exciting creation is our sports bra "The DE Sportief" which is set to take Derriere into the wider sporting arena, outside the equestrian world.

High-tech fabrics coupled with brilliant design-features are seeing this product becoming a market leader. It combines the perfect balance of compression and support leading to rave reviews from consumers.

How are the Derriere Equestrian products manufactured?

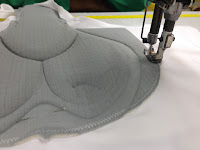

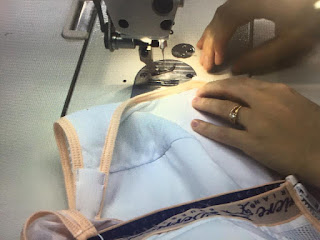

The manufacturing processes used for production, involves both the bonded and seamless technology.

Bonding fabric together, ensures reduced seamlines and stitching, this is an essential process to produce undergarments that have no abrasive edges and reduced stitched seamlines.

Bonding fabric together, ensures reduced seamlines and stitching, this is an essential process to produce undergarments that have no abrasive edges and reduced stitched seamlines.  Seamless Manufacturing is the new way of approaching the apparel culture. The introduction of the SEAMLESS manufacturing ability for producers has revolutionized the global underwear marketplace.

Seamless Manufacturing is the new way of approaching the apparel culture. The introduction of the SEAMLESS manufacturing ability for producers has revolutionized the global underwear marketplace.

The development of the single jersey electronic circular knitting machines for the production of seamless wear was a very innovative discovery and has revolutionized the underwear manufacturing process for underwear, outerwear, swimwear and sportswear.

The team that head up the manufacturing for Derriere are composed of textile engineers, specialized chemists, high level technicians, designers and fabric selection experts.

The team that head up the manufacturing for Derriere are composed of textile engineers, specialized chemists, high level technicians, designers and fabric selection experts.

The Derriere Equestrian® products go through more than 50 controls during their transformation in production, followed by further individual garment testing at quality control and then again at the packaging, shipment and warehousing stages. The final products are presented and packaged to an exceptionally high standard.

The manufacturing process involves: pattern formation, fabric coloring, pantone testing and layout, all prior to making it to the cutting table.

The manufacturing process involves: pattern formation, fabric coloring, pantone testing and layout, all prior to making it to the cutting table.

When working with our Italian fabrics for the bonded technology, all fabrics are pre tested and then cut supervised.

When working with our Italian fabrics for the bonded technology, all fabrics are pre tested and then cut supervised.

The traditional bundle formation is processed and all cut fabrics are then transported through to the bonding and stitching rooms. Specialized and highly trained seam technicians pull together the design formation and end users product.

From the design and manufacture of the Derriere Equestrian Padded Support System in Italy, through to full pull together of all product build of: Jacquard, Padding, Bonding, Seam Stitching, Seamless Weave production in Tunisia, the Derriere Equestrian Team are working hard to deliver to all of our buyers, the very best in equestrian and sporting apparel.

From the design and manufacture of the Derriere Equestrian Padded Support System in Italy, through to full pull together of all product build of: Jacquard, Padding, Bonding, Seam Stitching, Seamless Weave production in Tunisia, the Derriere Equestrian Team are working hard to deliver to all of our buyers, the very best in equestrian and sporting apparel.

No comments:

Post a Comment